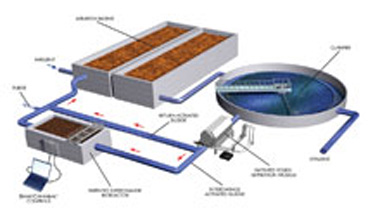

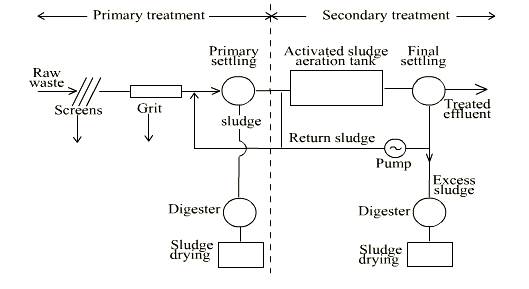

Activated Sludge Process:-

Introduction:-

In general, the activated sludge process is a continuous or semi continuous (fill

and draw) aerobic method for biological wastewater treatment, including carbonaceous

oxidation and nitrification. This process is based on the aeration of wastewater

with flocculating biological growth, followed by separation of treated wastewater

from this growth. Part of this growth is then wasted, and the remainder is returned

to the system. Usually, the separation of the growth from the treated wastewater

is performed by settling (gravity separation) but it may also be done by flotation

and other methods. Lichens also deals with modification of Activated sludge like

extended aeration etc.

Typical ASP (Activated Sludge Process) Process Flow diagram

Purpose:-

- oxidizing carbonaceous matter: biological matter.

- oxidizing nitrogeneous matter: mainly ammonium

and nitrogen in biological materials.

- removing phosphate.

- driving off entrained gases carbon dioxide, ammonia,

nitrogen, etc.

- generating a biological floc that is easy to settle.

- generating a liquor low in dissolved or suspended

material.

Rotating Biological Contactor(RBC):-

Introduction:-

Rotating biological contactors (RBCs) is a remediation technology used in the secondary

treatment of wastewater.

This technology involves allowing wastewater to come in contact with a biological

medium in order to facilitate the removal of contaminants. There are several different

designs now available, but in its simplest form a rotary biological contactor (RBCs)

consists of a series of discs mounted on a shaft, which is driven so that the discs

rotate at right angles to the flow of settled sewage.

Working Principle:-

The RBC process consists of a large disc with radial and concentric passages slowly

rotating in a concrete tank. The rotation and subsequent exposure to oxygen allows

organisms to multiply and form a thin layer of biomass. This large, active population

causes the biological degradation of organic pollutants. Excess biomass shears off

at a steady rate and is then carried through the RBC system for removal in a clarifier.

Applications:-

Residential/Commercial Complexes, Hotels, Restaurants, I.T. Parks, Theme Parks,

Amusement Parks, Golf Courses, Hospitals, Resorts, Camps, industrial Townships,

Educational Institutions, Isolated Clusters, Small & Medium Industries, Bus/Air/Rail

Terminals/Depots, etc. Besides this, Municipalities can adopt this technology for

conversion of sewage in to secondary grade reuse/recycle water and for aquifer recharge

programme.

Advantages:-

These rotating biological contactors offer many advantages like:

- The capability of handling a wide range of flows.

- Low power requirements

- Low sludge requirements

- Excellent process control.

- Maintenance and housekeeping requirements are

minimal.

- Only basic operator skills required.

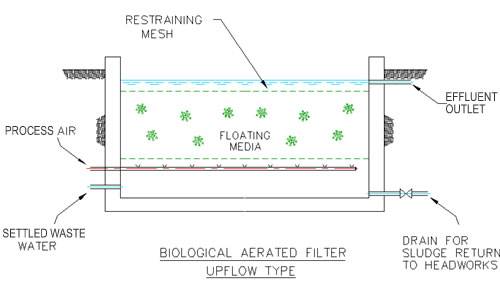

Submerged Aeration Filter(SAF):-

Introduction:-

Submerged Aerobic Filter (SAF) incorporates the advantages of Fixed

Film Technology combined with Fine bubble Diffused Aeration. SAF is highly suitable

for medium and low strength wastewater. Lichens design good quality

submerged aerated filter to reduce the amount of BOD and ammoniacal nitrogen in

settled sewage and industrial effluents. BOD removal efficiency possible of SAF

reactor is 95 - 97%.

Basic Structure :-

The Lichens SAF is a fabricated steel tank split into treatment cells, arranged

in series. Each cell houses a number of fine bubble membrane diffusers, which are

mounted below a packed rigid corrugated PVC media.

Working Principle:-

The Aerated effluent is passed via submerged media which acts as a physical support

for the growth of micro organisms. The Submerged aerated filters are seeded with

bacterial cultures to accelerate start-up. Air is introduced in the filter from

perforated pipes, from nozzles or from fine bubble diffusers located below the media

support structure.

Applications:-

- Municipal & Domestic Sewage Treatment

- Industrial Wastewater Effluents including

- Abattoirs

- Breweries

- Chemical Processing

- Dairies

- Distilleries

- Food Processing

- Pharmaceuticals

- Textiles

- Landfill and Bioremediation

- Permanent wastewater treatment plants

- Mobile emergency response treatment units

- Temporary treatment during planned maintenance

- Propping up biologically overloaded works

- Leachate treatment

- Industrial waste treatment

- Pilot studies

Advantages:-

- Lower Capital Cost.

- Higher BOD/ COD removal efficiency.

- Higher resistance to shock loading.

- Consistent performance.

- Lower Space/ Power Requirement.

- Quick & easy installation.

- Completely mixed and highly oxygenated discharge.

- Degradation of fats, oils and grease (FOG) .

- Non-chemical pH control.

- Protects biological secondary treatment from harmful

VOCs .

- Minimal O&M requirements.

- Guaranteed system performance

- Produces high effluent qualities; tolerates variations

in biological and solids loadings

- Eliminates the high headloss conditions allowing

the use of deeper media beds

- Eliminates the plugging potential typically associated

with BAF

- Eliminates air and water distribution problems

- No backwashes are required

- Process air blowers and low head feed pumps constitute

the only major power requirement

- Minimal process monitoring is required releasing

valuable operator time

- Utilizes a durable media with a long proven performance

life in excess of 20 years

- No moving or serviceable parts

- Small footprint

Moving Bed Bio Reactor (MBBR):-

Introduction:-

Wastewater treatment plants of a medium or small scale require a simple equipment

composition and easy maintenance. The Moving-Bed type bioreactor has largely simplified

the washing mechanism by washing filtering media parallel to the reactor processing.

Basic Structure:-

The Lichens MBBR is a variant of submerged aerated filter technology. It provides

a small footprint solution for carbonaceous, nitrification, C+N or in anoxic mode

for de-nitrification treatment with very low capital and operating costs together

with a low head loss.

The MBBR can be designed as a small footprint process solution for a new works,

or as a retro-fit to an existing activated sludge plant to increase capacity and

improve effluent quality. It can also be operated in applications of high ammonia

concentration – such as sludge liquor treatment or leachate treatment - with

the continuously moving bed format in order to provide the oxygenation required

for the higher load.

Working Principle:-

MBBR is a combination of attached growth as well as suspended growth which easily

degrade the organic matter present in waste water.

Applications:-

- Municipal & Domestic Sewage Treatment

- Industrial Wastewater Effluents including

- Abattoirs

- Breweries

- Chemical Processing

- Dairies

- Distilleries

- Food Processing

- Pharmaceuticals

- Textiles

- Landfill and Bioremediation

- Permanent wastewater treatment plants

- Mobile emergency response treatment units

- Temporary treatment during planned maintenance

- Propping up biologically overloaded works

- Leachate treatment

- Industrial waste treatment

- Pilot studies

Advantages:-

- Simplified facilities

The back washing device requires only the air-compressor for the air-lift,

and not the back-washing pump, blower, or tank that was needed for the fixed bed

type reactor.

- Simplified construction work

A steel reactor is manufactured at the factory to facilitate the field work, so

that the construction term can be shortened.

- Flexible response to the wastewater treatment projects

- Lower Capital Cost.

- Higher BOD/ COD removal efficiency.

- Higher resistance to shock loading.

- Consistent performance.

- Lower Space/ Power Requirement.

- Quick & easy installation.

- Completely mixed and highly oxygenated discharge.

- Degradation of fats, oils and grease (FOG) .

- Non-chemical pH control.

- Protects biological secondary treatment from harmful VOCs .

- Minimal O&M requirements.

- Guaranteed system performance

- Produces high effluent qualities; tolerates variations in biological

and solids loadings

- Eliminates the high headloss conditions allowing the use of deeper

media beds

- Eliminates the plugging potential typically associated with BAF

- Eliminates air and water distribution problems

- No backwashes are required

- Process air blowers and low head feed pumps constitute the only major

power requirement

- Minimal process monitoring is required releasing valuable operator

time

- Utilizes a durable media with a long proven performance life in excess

of 20 years

- No moving or serviceable parts

- Small footprint