Products >> Waste Water Treatment >> Package / Containerized

Sewage Treatment Plant

Introduction:-

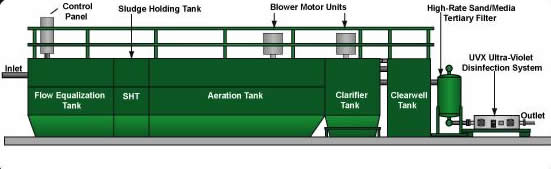

Package plants are prefabricated units designed for wastewater treatment that can

be brought to a site and installed. These units are most widely used to treat waste

water and removal of turbidity, color, and coli form organisms with filtration processes.

The package plants will include auxiliary equipment such as pumps and filters needed

for operation. Package plants are usually larger and more complex than the systems

described as alternative treatment. However, for larger flows or complex wastewaters,

they may be more effective. They may also take up less space. They require more

operator attention and higher-level operator training and commitment.

Package plants are pre-manufactured treatment facilities used to treat wastewater

in small communities or on individual properties. According to manufacturers, package

plants can be designed to treat flows as low as 10 KLD vor as high as 500 KLD.

We offer complete skid & truck mounted or containerized plant for the production

of drinking or process water from the wastewater itself.

The system have in-built diesel and kerosene generator with prime moving arrangement

to lift water from deep bore well and river. Treated water quality meets WHO standards

for drinking water standard.

Applications:-

This onsite treatment system is need based and modular which makes design and installation

easy. Different technologies could be successfully employed for site specific problem.

Under the correct operating conditions, appropriately designed package plants appear

capable of producing good quality effluent. Some of the important applications are

as follows:

- Mobile home parks

- Industrial manufacturing site

- Residential clusters

- Rural development

- Small communities

- Added capacity for Municipalities with existing services

- Small community

- Resort areas

- Schools and healthcare facilities

- Hotels and Resorts

- Construction Camps

- Food Processing Plants

- Areas accessible by air only

- Foreign Aid Missions

- Temporary Municipal Services

- Mining Camps

- Military Camps

- Construction Camps

- Environmental Emergencies

Advantages:-

- Treatment process retention time is reduced by more than 60%.

- Space and energy saving of more than 60 %.

- Ready for almost immediate installation.

- Easily transportable. Mounted on skid.

- Can be mounted on trailer (if required) and moved to different places.

- No major civil concrete works required at site.

- Saving on piping works requirement at site.

- Lockable from front. ( If Required )

- Capital, operation and maintenance costs are significantly lower than

a

- conventional activated sludge system of equal capacity

- Better at handling organic loading and flow fluctuations, and is suited

for sites that have a wide range of inflow and/or organic loadings

- Pre-Engineered and Pre-Fabricated, easy to transport and install as

they are shipped in one 20' shipping container, and only minor connections required

- Low waste sludge production due to long sludge ages

- Little operation and maintenance problems